How IoT quietly saves millions: a real-world lesson from a hospital oxygen plant

IoT is not about dashboards. It is about discipline, data, and timely action.

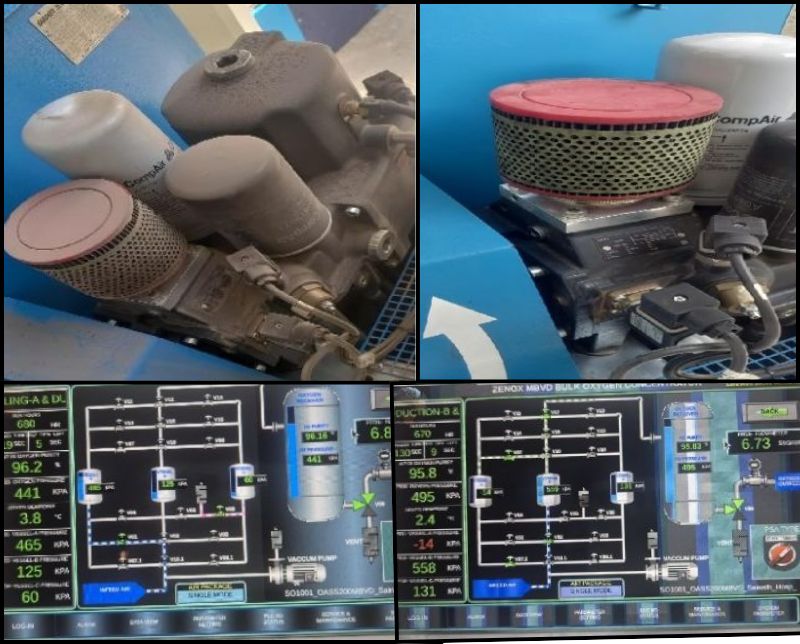

Here’s a simple but powerful case study from Sainatha Hospital, where Zenox installed an Oxygen MBVD™ plant.

The design intent

Plant capacity: 12 m³/hr

Average hospital consumption: 7 m³/hr

Standby logic:

Cut-out: 505 kPa

Cut-in: 440 kPa

Normal behavior: ~6 hours/day in standby

This is how efficiency is engineered — produce only what is required.

What went wrong

Ongoing construction near the plant led to heavy dust accumulation.

This caused choked air intake filters, reducing the Free Air Delivery (FAD) of the compressor.

The effect?

Plant stopped going into standby

Continuous running

Production valve, which normally opens at 540 kPa, started opening at 490 kPa

A subtle deviation — but a costly one if ignored.

Where IoT made the difference

Our IoT-enabled remote monitoring flagged the anomaly instantly.

The smart service engineer identified two possibilities:

Choked air filters

Air leakage in the system

A site visit confirmed the root cause: dirty filters.

Filters were cleaned — and bang on — the plant returned to its designed operating parameters.

The real savings

Energy saved: ~78 kWh per day

Annual cost savings: ~₹3,95,000 per year

From just cleaning air filters.

The larger lesson

Selling a product is only the first step.

Sustaining performance at design parameters is where real value lies.

IoT doesn’t just prevent failures —

👉 it protects efficiency,

👉 reduces operating costs, and

👉 builds long-term trust.

In today’s industrial world, maintenance intelligence is as important as manufacturing excellence.